We are a highly skilled team of dedicated individuals, with the latest equipment at our disposal. If you would like to work with us, please contact us directly. We have a variety of equipment that can be available for use by the wider research community, including academics and industry.

Institute of Compound Semiconductors

The CS Hub works in close collaboration with Cardiff University’s Institute for Compound Semiconductors (ICS). Offering state of the art facilities enabling commercial and academic exploitation of CS Technology, ICS has a mission to become the CS facility of choice.

The ICS moved to its new cleanroom in 2023, adjacent to the Translational Research Hub (TRH). This purpose built 1500m2 facility enabled the scale-up to 200mm (8”) wafer capacity, critical for industrial relevance. As part of Cardiff University’s new £300 million Innovation Campus, it combines cutting-edge research, technology transfer, business development and student enterprise. The ICS has received over £80 million investment for its new building and equipment including over £30 million of external investment. In addition to the 1500 square metre cleanroom, the dedicated characterisation and back end processing areas enable end-to-end processing of CS wafers.

ICS services can be used on a bespoke basis, depending on requirements. ICS are happy to provide a full service, where the user specifies the outcome, and ICS Engineers deliver the finished product. ICS can also provide training and guidance to users’ staff.

University Growth Facilities

Complementary growth facilities are provided at Manchester, UCL, Sheffield and Cardiff:

Manchester

- Two molecular beam epitaxy (MBE) systems, including high uniformity 200mm (8″) MBE, will focus on growth of GaAs for e.g. 2DEG magnetic sensors.

- Local 150mm fabrication and characterisation facilities include DCXRD, PL, CV and RF on wafer to 110GHz.

UCL

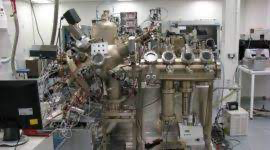

Molecular Beam Epitaxy (MBE) based at UCL provides high-quality III-V and group IV semiconductor material growth which expend the limitation of semiconductor materials. The twin chamber MBE system consists of one Vecco GEN 930 Group III-V and one Vecco GEN 930 Group IV MBE. Group III-V MBE system has solid source Indium, Gallium, Aluminum, Phosphorus, Arsenic and Antimony materials. It also has the doping cells Silicon and Beryllium. An additional Phosphorus recovery system is needed to eliminate the contamination of residual Phosphorus. As for Group IV MBE system, it has Germanium, Silicon, and Tin sources, with doping cells Boron and Antimony and a Si E-beam source. Now the twin chamber MBE system mainly focused on the researches of low-dimensional structures including quantum wells, nanowires, and quantum dots.

The National Epitaxy Facility In Sheffield plays a central role in enabling UK University research through provision of high quality Semiconductor Epitaxy for custom designed structures and devices. The facility has expanded from the provision of III-V materials and devices to include group Iepitaxy and hybrid III-V/Group IV epitaxy. As well as supporting UK university research the facility plays an equally significant role in enabling developments in UK industry with many companies utilising expertise, knowledge and world class facilities to further their businesses.

Cardiff University

- A Welsh Assembly Ser Cymru investment has supported new MBE GaN and MBE and MOVPE As and Sb based systems.

- Fabrication in the ICS is supported by materials and optoelectronic (400-4000nm) and RF device characterization (to 120 GHz). This world leading capability enables research on the important CS material families and includes the wafer size scale-up and integrated epitaxial growth and processing, with direct comparisons between small and large scale, necessary for manufacturing. It allows the hub to fund personnel and consumables only to leverage the largest effect. ICS and CSC facilities provide laboratory and specialist clean-room space for co-located academics and industrialists to create maximum innovation and translational impact for the next stage beyond the EPSRC Hub.